We conduct thorough inspections at every stage of the production process.

Nickel pipes are specialized piping solutions made predominantly from nickel—a highly versatile metal known for its outstanding corrosion resistance. These pipes are widely used across industries such as chemical processing, petrochemicals, power generation, and aerospace, where durability and reliability are essential.

One of nickel's standout characteristics is its ability to resist corrosion and oxidation, even at elevated temperatures. This makes nickel pipes exceptionally suitable for transporting corrosive gases and fluids in harsh industrial environments. Beyond corrosion resistance, nickel also provides excellent mechanical strength and thermal stability, ensuring dependable performance under extreme conditions.

| Pipe Specifications | ASTM B622 / ASME SB622 |

|---|---|

| Tube Specifications | ASTM A619, B626 / ASME SA619, SB626 |

| Dimensions | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| Seamless Pipe & Tube Size | 1/2″ NB – 16″ NB |

| Welded Pipe & Tube Size | 1/8″NB TO 30″NB IN |

| EFW Pipe & Tube Size | 6″ NB – 24″ NB |

| Tube Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock |

| Thickness | 0.35 mm – 50 mm |

| Specialized in | Large Diameter Pipe Size |

| Schedule | SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, SCH 80S, SCH60, SCH80, SCH120, SCH140, SCH160, SCH XXS, SCH XS |

| Type | Seamless Pipes, ERW Pipes, Welded Pipe, Fabricated Pipes, Electro polished Pipe, Polished Pipe, Hollow Pipes |

| Form | Round, Square, Hydraulic, U Shape, Rectangular, Pan Cake Coils, Coiled, Hex, Honed, Etc |

| Length | Single Random, Double Random & Required Length. |

| End | Plain End, Beveled End, Treaded End |

Steel Craft Alloys is a recognized leader in the manufacturing and supply of Nickel Alloy Bars in India. Renowned for its commitment to quality and reliability, the company has built a strong reputation for delivering premium-grade products that comply with rigorous industry standards.

Steel Craft Alloys produces Nickel Alloy Bars that meet the demands of a wide range of industrial applications. Its modern manufacturing infrastructure ensures precision, consistency, and superior mechanical performance, with each bar offering excellent corrosion resistance and durability. The company offers a comprehensive selection of Nickel Alloy Bars in various grades and specifications, providing flexible solutions tailored to specific customer needs. With stringent quality control and adherence to international standards, Steel Craft Alloys stands out as a trusted partner for critical sectors such as aerospace, petrochemicals, and heavy manufacturing.

| Specifications | ASTM B166, B446, B637, ASME SB166, SB446, SB637 |

|---|---|

| Dimension Standard | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Bar Diameter | 3 ~ 800mm |

| Hex Bar size | 2-100mm A/F |

| Flat bar size | Thickness: 2 -100mm. Width: 10 to 500mm. |

| Square bar size | 4 to 100mm |

| Rectangular Bars | Size: 33 x 30mm to 295 x 1066mm. Thickness: 3.0 to 12.0mm. |

| Hollow Bars | 32mm OD x 16mm ID to 250mm OD x 200mm ID |

| Billet Size | 1/2 to 495mm Diameter |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| Bar Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Rolled Bars Condition | Hardened & tempered, annealed |

| Cold Rolled Bar Technique | Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Form | Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

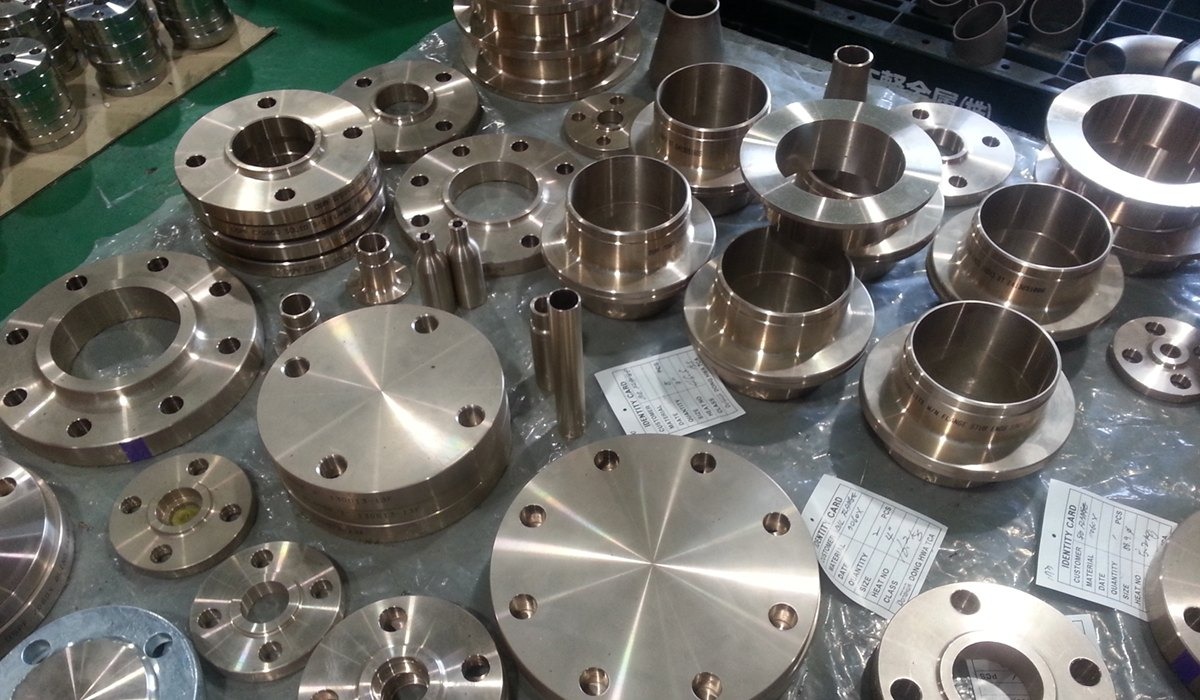

Steel Craft Alloys is a leading manufacturer of high-quality Nickel Pipe Fittings, recognized for its unwavering commitment to excellence and customer satisfaction. We offer a comprehensive range of precision-engineered products designed to serve the diverse needs of global industries. Our focus on innovation, quality craftsmanship, and dependable service distinguishes us as a trusted name in nickel alloy solutions.

Among the most commonly used grades are Nickel 200 and Nickel 201—known for their superior thermal and electrical conductivity. These grades are widely utilized in sectors such as electronics, aerospace, and food processing. Our nickel alloy fittings portfolio includes a variety of configurations such as elbows, tees, reducers, couplings, and flanges. Each product is crafted with precision to ensure long-lasting durability and performance. Whether you require seamless or welded fittings, or standard and custom dimensions, Steel Craft Alloys is your reliable source for top-tier nickel alloy pipe fittings.

| Specifications | ASTM B366 / ASME SB366 |

|---|---|

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Size | Seamless Butt Weld Fittings: 1/2" - 10" Welded Butt Weld Fittings: 1/2" - 48" |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) ASTM B366 Nickel Buttweld Fitting |

| Type | DN15-DN1200 |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom MSS Sp-43 Nickel Pipe Fitting |

| Elbows | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Connection | Welding |

| Manufacturing process | Forge, Cast, Push, Press, etc. |

| Key markets and industries |

|

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Specialized manufacturer of | 90 Deg Elbows, 45 Deg Elbows, Tees, Crosses, Reducers, Pipe Cap, Stub End, Pipe Bend |

Steel Craft Alloys is a recognized leader in the manufacturing of premium-quality Nickel Flanges. Driven by a commitment to excellence and continuous innovation, we have earned a reputation as a reliable nickel flanges manufacturer and supplier, delivering dependable solutions for a wide range of industrial applications.

At Steel Craft Alloys, we offer a diverse range of nickel flanges in multiple grades to meet specific industrial needs. Our core offerings include Nickel 200 and Nickel 201 flanges, both known for their excellent mechanical and chemical properties. Each flange is precisely engineered and manufactured to ensure superior strength, performance, and resistance under the most challenging operating conditions.

| Standard | ASTM B564 / ASME SB564 |

|---|---|

| Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Size | 1/2" (15 NB) to 48" (1200NB), DN10~DN5000 |

| Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| JIS | 16 K, 5K, 10 K, 20 K, 30 K, 40 K, 63 K |

| Flange Connection / Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove, Flange Pipe. |

| Types of Flanges | Threaded / Screwed / Forged / Plate |

| Coating | Yellow Transparent, Zinc Plated, Anti-rust Paint, Oil Black Paint, Cold and Hot Dip Galvanized |

| Test Of Flange | Direct-reading Spectrograph, Ultrasonic flaw detector, Magnetic particle detector, X-ray detector, Hydrostatic testing machine. |

| Production Technique Used | Heat treated, Forged and Machined |

| Equipment | Press machine, Bending machine, Pushing Machine, Sand-blasting machine, electric bevelling machine etc. |

| Test Certificates | EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report, etc |

Steel Craft Alloys is a trusted manufacturer, supplier, stockist, and exporter of high-quality Nickel Alloy Fasteners, meticulously produced to meet both national and international standards. We maintain a comprehensive inventory of Nickel Alloy Fasteners available in a wide range of sizes, thicknesses, widths, and finishes. Additionally, we offer custom manufacturing solutions tailored to meet specific industry needs—all at highly competitive prices.

Our fasteners, including Nickel Alloy Bolts and Nickel Alloy Screws, are made from premium-grade alloys composed of nickel blended with elements such as chromium, molybdenum, iron, copper, and cobalt. These materials are selected for their superior resistance to corrosion, high temperatures, and mechanical stress, making our fasteners the ideal choice for critical applications in harsh and demanding environments where standard options may fail.

| Standard | ASTM B574 / ASME SB574 |

|---|---|

| Bolt / Screw Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Nuts Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Washers Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Machine Screws Size | M1.6 – M12 |

| Self Tapping Screw Size | No.2 – No. 14 |

| Length | 3 mm to 200 mm |

| Threads | UNF, BSW, BSF, METRIC, UNC, or as required |

| Fasteners |

|