We conduct thorough inspections at every stage of the production process.

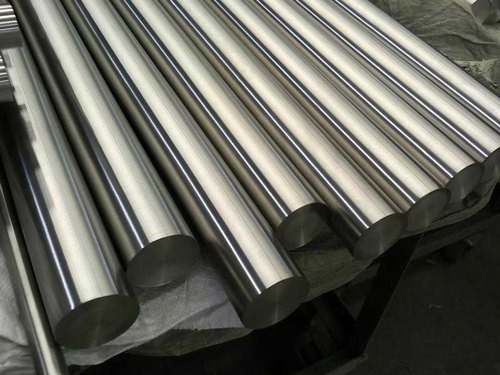

Round bars are metal rods in a cylindrical shape widely applied in construction, manufacturing, and fabrication. They come in various materials, including stainless steel, carbon steel, aluminum, and brass, each having various mechanical properties tailored to meet distinct applications. Round bars are applied extensively to shafts, supports, axles, and fasteners because of their durability as well as uniform cross section.

Stainless steel and duplex steel are both corrosion-resistant alloys used extensively across most industries owing to these alloys' durability and strength. Stainless steel, containing mostly iron, yet sometimes incorporating additional elements like nickel and molybdenum, has superior rust- and staining-resistance, making stainless steel highly suited to applications where cleanliness and aesthetics matter, like food preparation and equipment in medicine. Duplex steel, a hybrid of austenitic stainless steel and ferritic stainless steel, has inherited favorable aspects of both steel types.

| Range | 3.17 MM TO 350 MM DIA |

|---|---|

| Form | Round. |

| Stainless Steel |

ASTM / ASME SA 276 TP 304, 304L, 309S, 309H, 310S, 316, 316L, 316 TI, 317, 321, 347, 410, 420, 430, 431, 440A, B & C, 446 ASTM / ASME SA 479 TP 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316H, 316L, 316 TI, 317, 321, 321H, 347, 347H, 410, 430, 431 & 444. |

| Duplex Steel | ASTM / ASME SA 276 UNS NO. S31803, S32205, S32550, S32750, S32760. |

Round bars made of carbon and alloy steel are fundamental materials found in a broad variety of industries owing to their durability, versatility, and strength. Carbon steel round bars, in low, medium, and high carbon grades, find applications in construction, automobile components, machinery, and general engineering owing to a high tensile strength as well as affordability. Alloy steel round bars, conversely, are supplemented by additional elements, including molybdenum, chromium, nickel, and vanadium, to enhance a range of properties like corrosion resistance, hardness, as well as resistance to wear.

| Range | 3 MM TO 350 MM DIA |

|---|---|

| Standard | ASTM, ASME, AISI, EN, SAE, ETC |

| Finish | Bright, Polish & Black. |

| Grade | A182 - F5, F9, F11, F12, F21, F22 & F91. |

| Form | Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc. |

| Application | Shafts, Axels, Bolts, Sprockets, Piston Rods, Rams, etc. |

Nickel-copper alloy round bars are high-end materials that possess excellent corrosion resistance, superior thermal and electrical conductivity, and high mechanical strength properties. The bars are widely used in a variety of different industries, from marine engineering to chemical processing, power generation, and oil & gas operations. The nickel-copper mixture provides superior durability, particularly in hostile environments like saltwater or acids. The bars are also preferred because of ease in fabrication and weldability, enabling them to be a universal selection for shafts, fasteners, fittings, and valves amongst other components.

| Range | 3.17 MM TO 350 MM DIA |

|---|---|

| Form | Round |

| Nickel Alloy |

ASTM / ASME SB 160 UNS 2200 (NICKEL 200) / UNS 2201 (NICKEL 201) ASTM / ASME SB 164 UNS 4400 (MONEL 400) ASTM / ASME SB 425 UNS 8825 (INCONEL 825) ASTM / ASME SB 166 UNS 6600 (INCONEL 600) / UNS 6601 (INCONEL 601) ASTM / ASME SB 446 UNS 6625 (INCONEL 625) ASTM / ASME SB 574 UNS 10276 (HASTELLOY C 276) ASTM / ASME SB 472 UNS 8020 (ALLOY 20 / 20 CB 3) |

Hastelloy round bars are high-performance alloy bars that are renowned for their superior resistance to corrosion, most notably in adverse chemical environments. Composed of a significant proportion of a nickel-molybdenum or a nickel-chromium-molybdenum alloy Hastelloy round bars are extensively applied across various industries, from chemical processing to aerospace, power generation, and marine. Hastelloy bars are found in various grades such as Hastelloy C-22, C-276, and B-2, and are frequently selected when strong oxidizers, acids, and high temperature applications are involved. They are a favored choice of material when components such as valves, shafts, heat exchangers, and pressure vessels need both corrosion resistance as well as strength.

| Grades | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000 |

|---|---|

| Type | Hastelloy Round Bar Hastelloy Bright Bar Hastelloy Polish Bar Hastelloy Black Round Bar Hastelloy Forged Bar Hastelloy Forged Round Bar Hastelloy Hex Bar Hastelloy Forged Hex Bar Hastelloy Flat Bar Hastelloy Rod |

Inconel round bars are a high-performing alloy containing mostly nickel, chromium, and iron along with trace elements of other metals. With a strong resistance to oxidation, corrosion, and stability at high temperatures, Inconel round bars find applications in aerospace, power generation, and chemical processing industries. These bars are strong enough to withstand extreme environments, high temperatures above 1,000°F (538°C), without compromising on integrity.

| Grades | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 |

|---|---|

| Sizes | 1mm to 200mm diameter |

| Type | Bars, Rods, wire |

| Standard | ASTM, ASME, API, AISI, BS, ANSI, DIN, JIS, MSSP, NACE |

Monel round bars are an alloy of copper and nickel, consisting of about 67% nickel and 30% copper, along with minor components of iron, manganese, and silicon. Monel round bars are highly resistant to corrosion, especially in marine and acidic environments, making them a strong candidate for applications where durability in harsh environments. Monel round bars are also resistant to stress corrosion cracking, making them a favorable candidate for applications that are being subjected to highly corrosive substances.

| Grades | Monel 400, Monel k500 |

|---|---|

| Range | 5 mm dia To 500 mm dia in 100 mm TO 6000 mm Length |

| Standard | ASTM / ASME SB 164 |